The tire barcode information management system

The tire barcode information management system

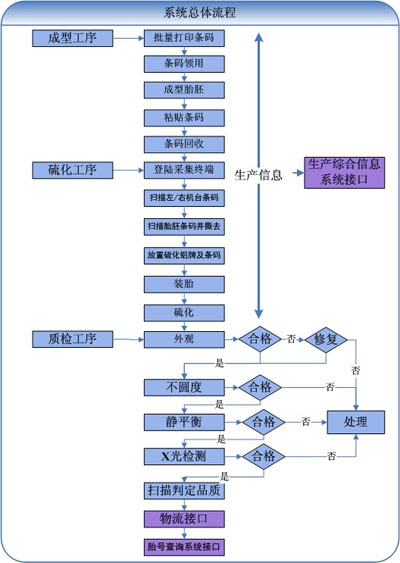

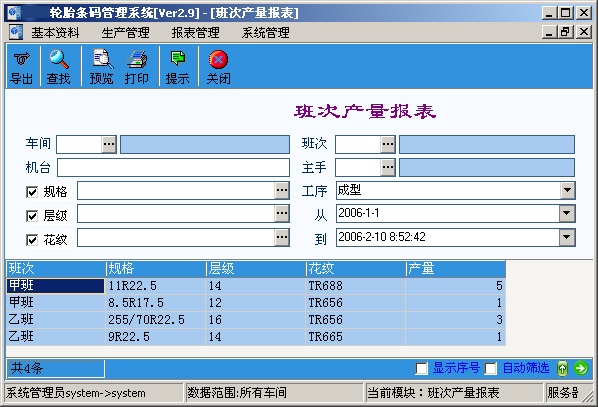

In the tire manufacturing industry, tire barcode information management system for mixing, rolling tread side pressure lined pressure a bead, cutting, molding, curing various production processes, quality inspection provides information management. Molding, vulcanizing production information accurate, real-time recording, the implementation of this system can not only increase the accuracy of the information forming sulfide quality retrospective, real-time, but also the the existing fetal No. chaotic management, the accuracy of the inventory information through bar code identification, tires the information is not easily traced back more difficult to meet the requirements of the automobile recall system marked improvement can be obtained.

The main technical implementations

System architecture: the system is based on C / S structure, using delphi and java language development, background SQLServer database.

Information delivery media: barcode labels, wireless local area network Ethernet network and industrial barcode just a summary of the data transfer from the index effect, detailed data needed network pass.

The information identifying ways: The system uses a combination of wireless data collector and wired barcode scanning equipment information to identify mobile information collection aspects of wireless acquisition, in some relatively fixed production processes, in order to save the cost of doing business to consider only wired barcode scanning equipment for data acquisition.

Network structure: the use of enterprise information management center to establish a separate LAN and wireless LAN network structure combined with the existing network structure in each factory, in every factory, to connect the various production processes (, curing, quality inspection, storage, etc.). Star local area network servers, clients, and the site of the factory workshop AP to establish and communicate, AP collection terminals to form a wireless LAN using TCP / IP protocol, adopted the the 802.11B protocol for communication, process data upload, download and check through AP connectivity.

Protocol support: the need for the support of the TCP / IP communication protocol, 802.11b wireless network communications and 802.3af network supply agreement and other agreements.

Server set up: the main double hot backup server to ensure the uninterrupted operation of the system.

Add.:Room 802, Block E, Power Creative Building, Shangdi East Road No. 1 , Haidian District, Beijing

Add.:Room 802, Block E, Power Creative Building, Shangdi East Road No. 1 , Haidian District, Beijing

Hotline:400-818-6918

Hotline:400-818-6918

Web:www.hzdy998.com

Web:www.hzdy998.com